Piezo sounder element manual#

Using a manual or digital potentiometer.

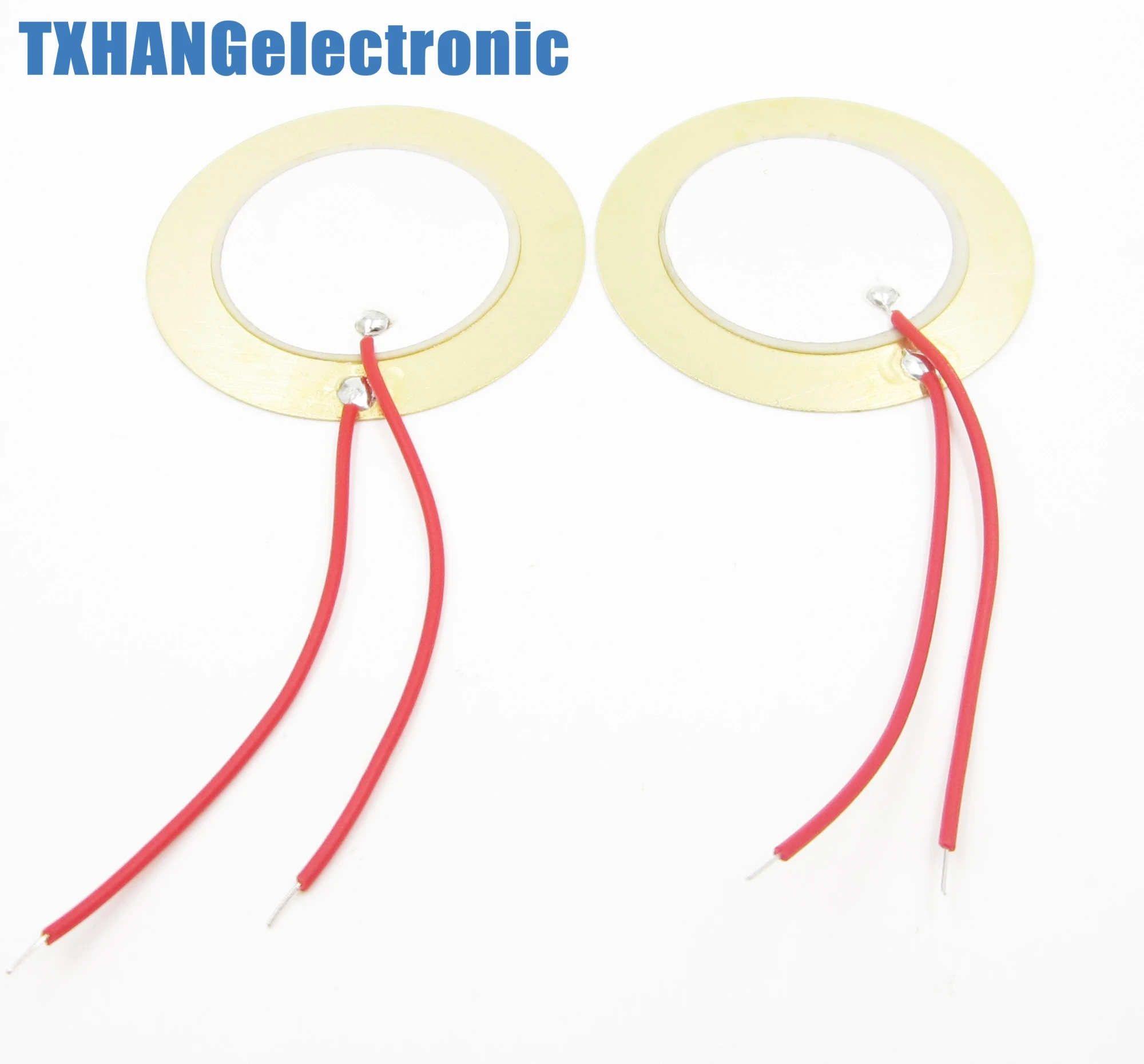

There are several ways of electronically controlling the voltage including: Audible alarms are available that have sound levels as soft as 55 dB at 2 feet and as loud as 110 dB at 2 feet. The chart below shows where some common sounds fall on this dB scale. The decibel sound level scale is an arbitrary scale that ranges from 0 dB (threshold of hearing) to 130 dB (threshold of pain). This signal can be fed back into the circuit to allow the sounder element to self-tune itself to the transducer’s resonant frequency. This third terminal provides a feed-back signal that is 180 degrees out of phase with the drive signal. Self-Drive type devices provide a 3 rd terminal that connects to an isolated portion of the piezoelectric transducer. This frequency where the transducer performs the best is called the resonant frequency. Every transducer has one frequency where it flexes more efficiently producing the louder sound levels. To increase the size of the air pressure waves (and thus the sound level), the transducer element must be mounted inside an acoustic chamber that is optimized for the transducer size and resonant frequency. However, it is rare to apply this much voltage to a transducer as you reach a point of diminishing returns for voltages much greater than 32 volts.īy itself, the sound level produced by a transducer element is insignificant. This maximum voltage is somewhere around 40 to 50 volts. However, the ceramic portion of the transducer can only bend so far before there is a risk of a catastrophic failure. The larger the voltage of the applied wave-form, the larger the amplitude of the air pressure waves resulting in a louder sound level. If this oscillation occurs in the audible frequency range (1 Hz to 20 kHz), then air pressure waves are produced that the human ear interprets as an audible sound. By applying a sinusoidal wave-form at an appropriate frequency, the transducer will physically deflect in one direction and then in the opposite direction following the shape of the input wave-form. The above picture shows a bare piezoelectric sounder element. The piezoelectric sounder element consists of a metal disc that has a special ceramic materialīonded to it that physically bends when voltage is applied to it. Piezoelectric electronic audible alarms work by converting the user input voltage to an appropriate oscillating signal that is applied to a sounder element that is mounted in a housing. Operation of Piezoelectric Audible Alarms If you need to wash the alarms after a soldering operation, it is strongly recommended to use an alarm that comes with a wash label that keeps the washing fluid from getting inside of the front cavity.

However, fluid sitting inside the front cavity can obstruct the operation of the device causing the sound level to decrease significantly. If the back of the alarm is sealed with epoxy or other material, the “guts” of the alarm (including the circuit board and components) are protected against fluid intrusion.

Piezo sounder element Pc#

The above picture can be interpreted to represent a board mount package with pc pin terminations, but the same concept is used when building audible alarms in other mounting configurations such as SMT, Flange Mount, and Panel Mount alarms. If the alarm is an indicator that contains a circuit board, the circuit board is attached to the piezoelectric sounder element via soldered wires. The area in front of the transducer element including the front hole opening forms an acoustic cavity that lets the sound radiate out with the most efficiency (i.e.

The above cross section picture shows the basic elements used in a piezoelectric audible alarm.

0 kommentar(er)

0 kommentar(er)